RACON 8 ST, SMT, 6 ± 1 N, 1 NO

Article number: 1.14.108.803/0000

Technical data

|

General |

|

| Color | blue |

| Operating temperature, min. | -40 °C |

| Operating temperature, max. | 125 °C |

| Storage temperature, min. | -50 °C |

| Storage temperature, max. | 85 °C |

| illuminated | No |

| Soldering | Reflow |

| Solder heat resistance according to standard | DIN EN 60068-2-58 |

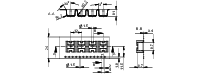

| Packaging | Blister |

| Packaging unit | 1,000 pcs. |

| Operating life | 50,000 cycles |

| B10 | 65,000 cycles |

| Degree of protection, front side, according to ISO 20653 | IP67 (IP6K7) |

| Degree of protection on rear side acc. to ISO 20653 | IP67 (IP6K7) |

| MSL Moisture Sensitivity Level | 1 |

| Corrosive gas testing according to standard | Yes |

| Minimum order quantity (MOQ) | 1,000 pcs. |

| RoHS compliant | Yes |

| REACH compliant | Yes |

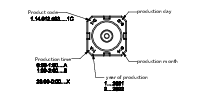

| Product code | TI |

| Country of origin | DE |

|

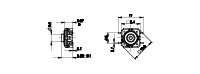

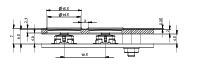

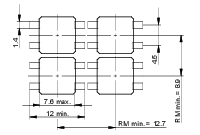

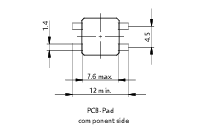

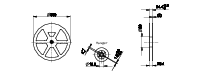

Mounting dimensions |

|

| Outside dimension, length | 8.4 mm |

| Outside dimension, width | 8.4 mm |

| Installation height | 5 ± 0.1 mm |

| Grid, min. | 8.9 x 12.7 mm |

|

Mechanical characteristics |

|

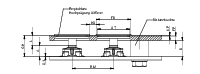

| Terminal on the rear | SMT |

| Actuation function | momentary contact function |

| Operating force, max. | 8 N |

| Operating force, min. | 6 ± 1 N |

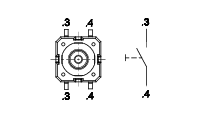

| Contact function | 1 NO |

| Contact system |

Snap-action contact

SPST - Single Pole Single Throw |

| Contact material | Gold |

| Solderability | Yes |

| Bounce time at 10 mm/s | <5 ms |

| Switching travel | 0.47 ± 0.15 mm |

|

Electrical characteristics |

|

| Rated voltage, min. |

|

| Rated voltage, max. | 35 V |

| Rated current, min. |

|

| Rated current, max. |

|

| Rated power, max. | 1 W |

Drawings

Description

Our top-quality RACON 8 tactile switches – in dimensions 8.4 x 8.4 mm – feature an unmistakeable click, high switching reliability, and a sealed contact system. That has made RACON the standard in many industries. Whether for automotive applications, systems with keycaps, or membrane keyboards, RACON impresses in the THT or SMT versions – for your application too.

RACON 8 tactile switches can be arranged individually, in rows or as key blocks. When used beneath membrane overlays, the RACON key switches should be combined with plungers. Suitable for the most important soldering techniques.

- Soldering bath for THT versions

- Reflow soldering for SMT versions

- Vapor phase soldering for SMT versions

- Manual soldering

- Processing of the SMT designs with SMT automatic assembly machines

- IMDS entry